etavalve

Technology

Identified Problem

Heavy industries such as metal, glass, and cement production, as well as emerging CO2-negative pyrolysis processes, release significant amounts of heat during their operations. Existing technologies are unable to effectively utilize this thermal energy especially at temperatures between 400 °C and 900 °C and power levels below five megawatts. This is exactly the operating range that the etavalve engine aims to address.

Our Solution

Our new piston-based thermal engine is designed to operate using the well-known Brayton cycle, also known as Joule cycle or gas turbine process. In this cycle, air as a working fluid is compressed, then heat is added at a constant pressure, and finally, it is expanded to generate work.

Input values

Available temperature

°C

Available thermal power

kW

Annual operation time

hours

Your current cost for electricity

CHF/kWh

Use the heat!

Save money and the planet!

Output values

282k CHF

299 t CO 2 eq

Annual savings

28%

0%60%

Expected efficiency

141

kW

Expected electrical power output

Use the heat!

Save money and the planet!

The Core Technology

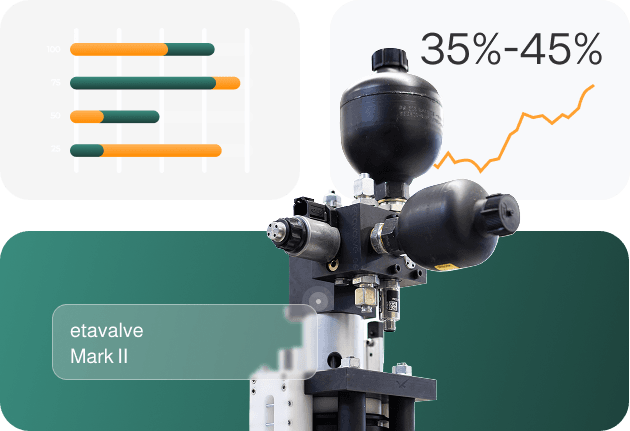

As the airflow of the compressor and the expander must be precisely coordinated, the feasibility of a piston-based Brayton engine relies on the implementation of a variable valve actuator. We have developed such an actuator – highly efficient and fully automated.

This patented core technology allows the piston-based Brayton engine, unlike the gas turbine, to dynamically adjust to the desired power and to fluctuations of the heat source.

This patented core technology allows the piston-based Brayton engine, unlike the gas turbine, to dynamically adjust to the desired power and to fluctuations of the heat source.

Frequently asked questions

Focusing on quality,we maintain customer trust